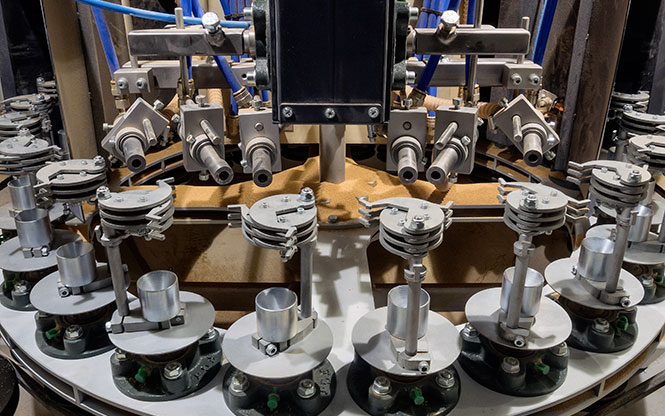

Abrasive media used in screw cleaning machines are those which do not damage the surface of blasted components, it is so called non-abrasive soft cleaning.

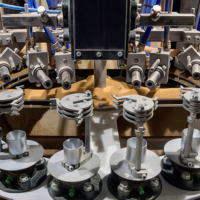

Depending on the necessary level of cleaning, type, and size of a screw, an operator sets an individual program. The cleaning process itself is then fully automatic and operator is free to work on something else in the meantime. If an operator finds further cleaning necessary when checking the result, he / she can choose an additional program or spot cleaning via remote control.

Screw cleaning machines are controlled on a touch screen with the software enabling to set several levels of authorization such as operator, supervisor, and maintenance.

The machine is standardly provided with workplace safety equipment such e.g. photoelectric sensor etc.

For cleaning other than cylinder-shaped objects you can choose different types of blast machines with suitable abrasive medium. Click here to see an example.